Applications

Projection welding

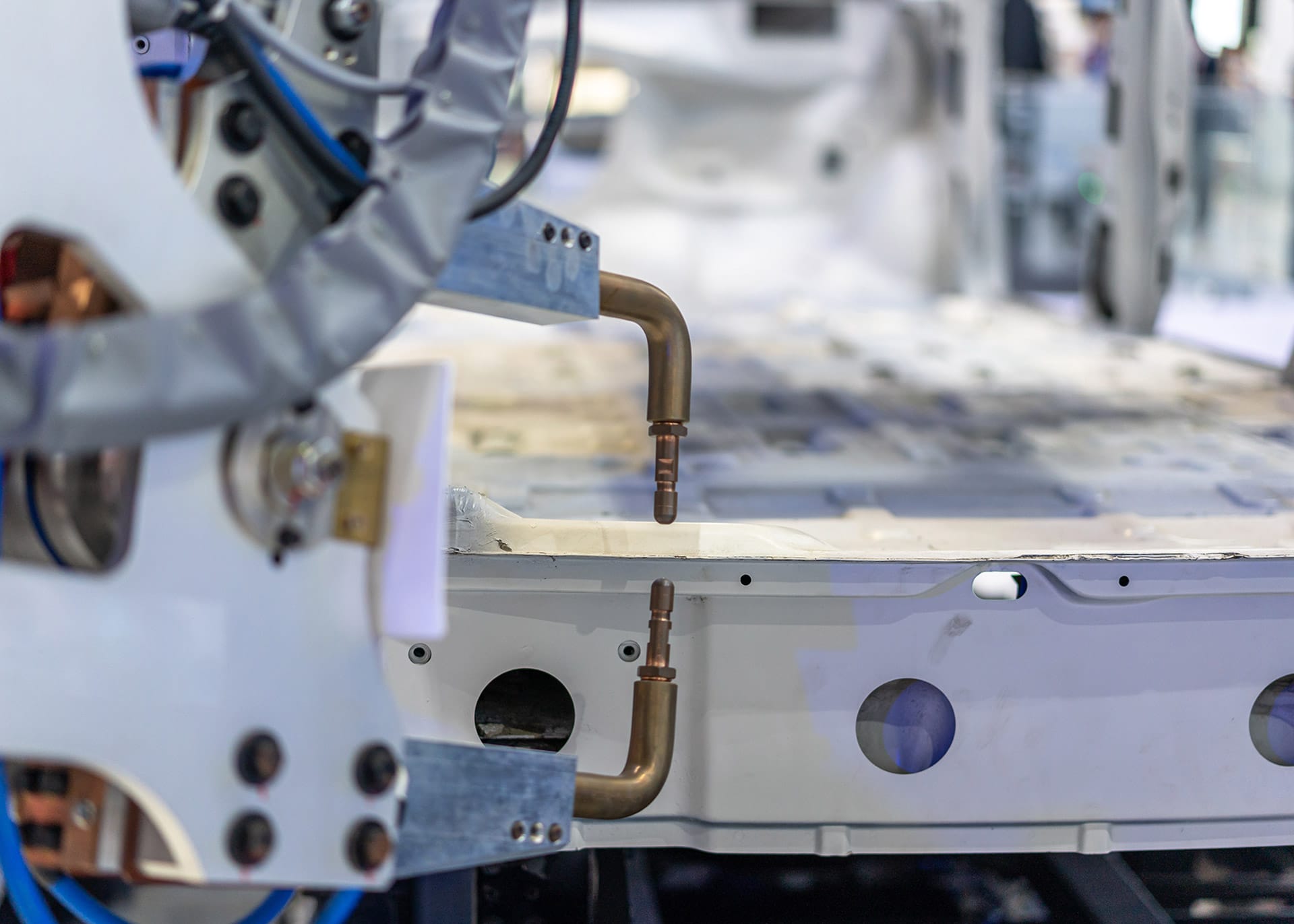

Projection welding is a very powerful variant of resistance pressure welding. It offers advantages in automation, as multiple spots can be welded during one operation. This process is mainly used in mechanical engineering.

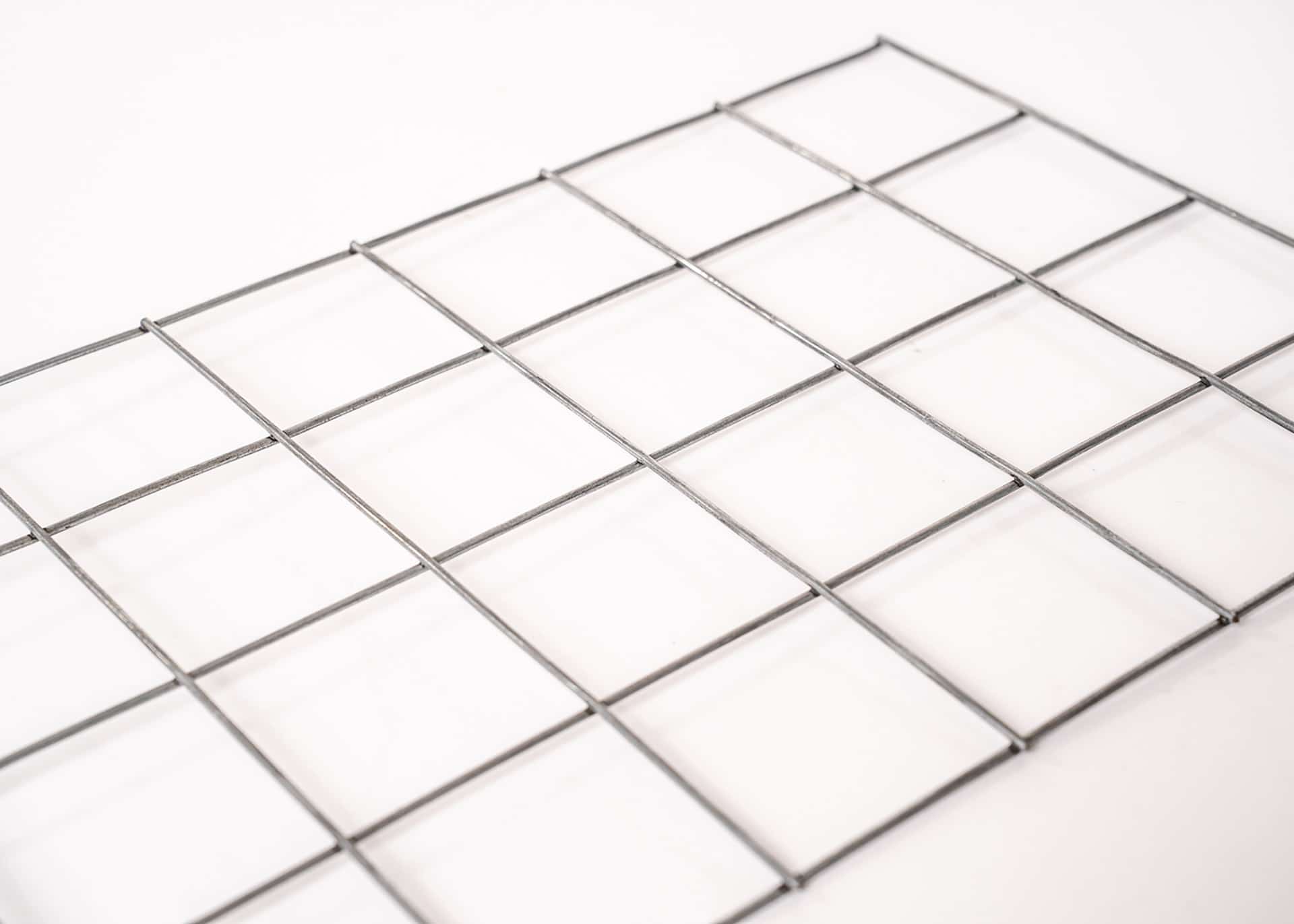

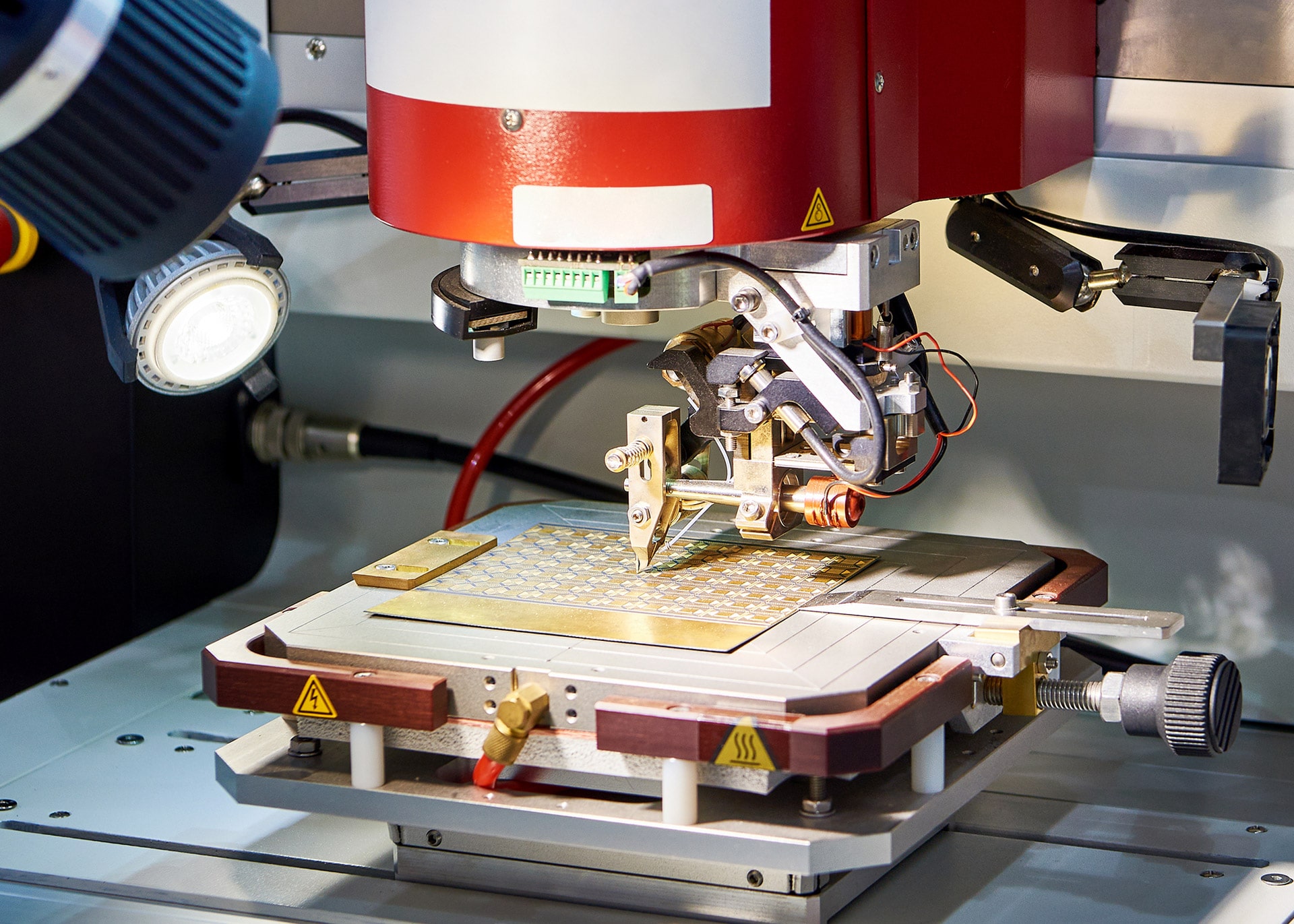

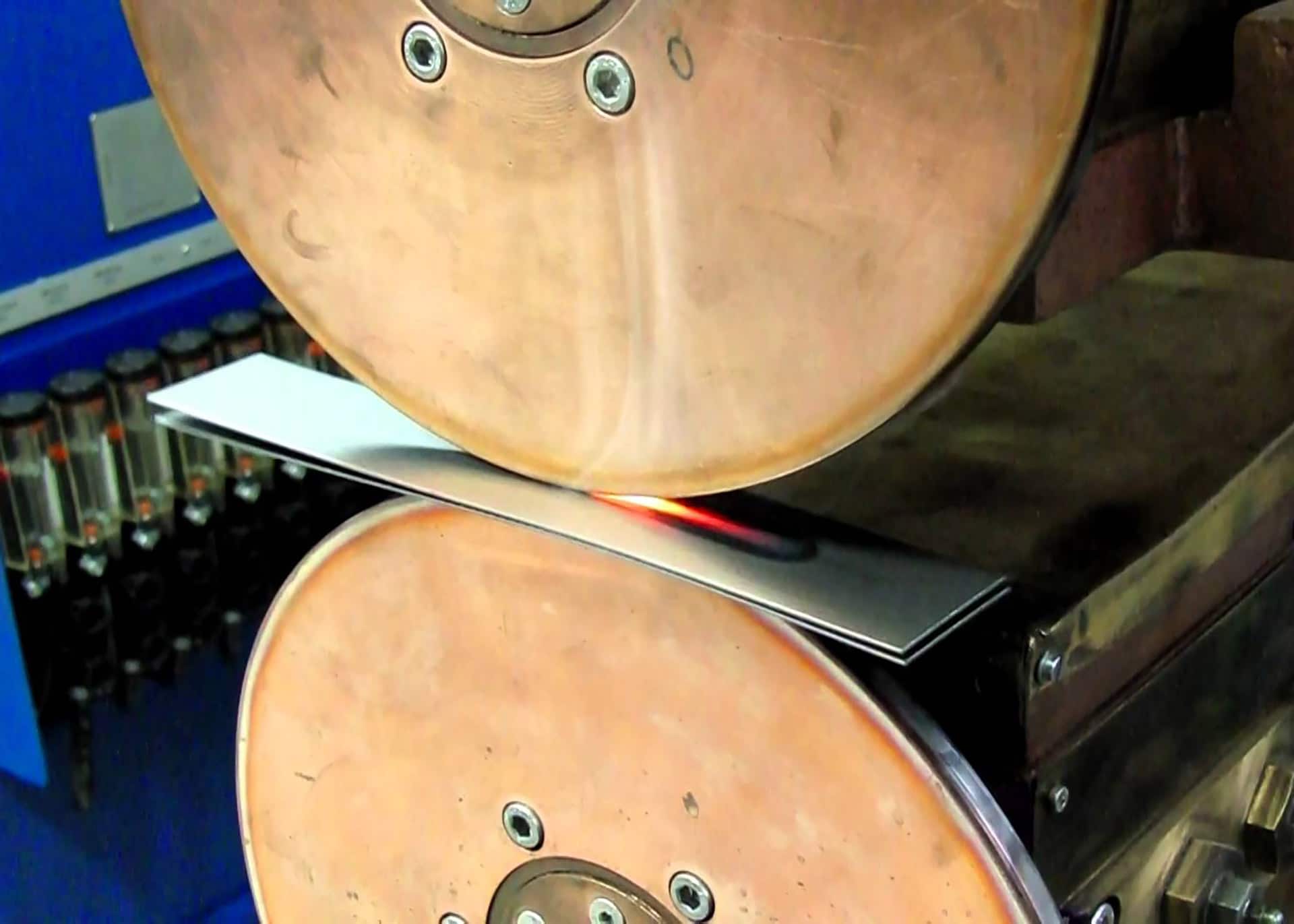

One or more elevations (weld projections) are introduced into one of the components to be joined. Due to the geometry of the projection, the area of current transfer is precisely defined, because only the projection now rests on the component to be welded. In contrast to spot welding, other electrodes are also used: flat copper electrodes. During the welding process, the projection partially melts and forms a bond with the pressed-on component.

The high currents required for projection welding are a specialty of Harms & Wende. Several hundred kA of current, when using inverter technology, are technical pioneering achievements of the Harms & Wende development.