Applications

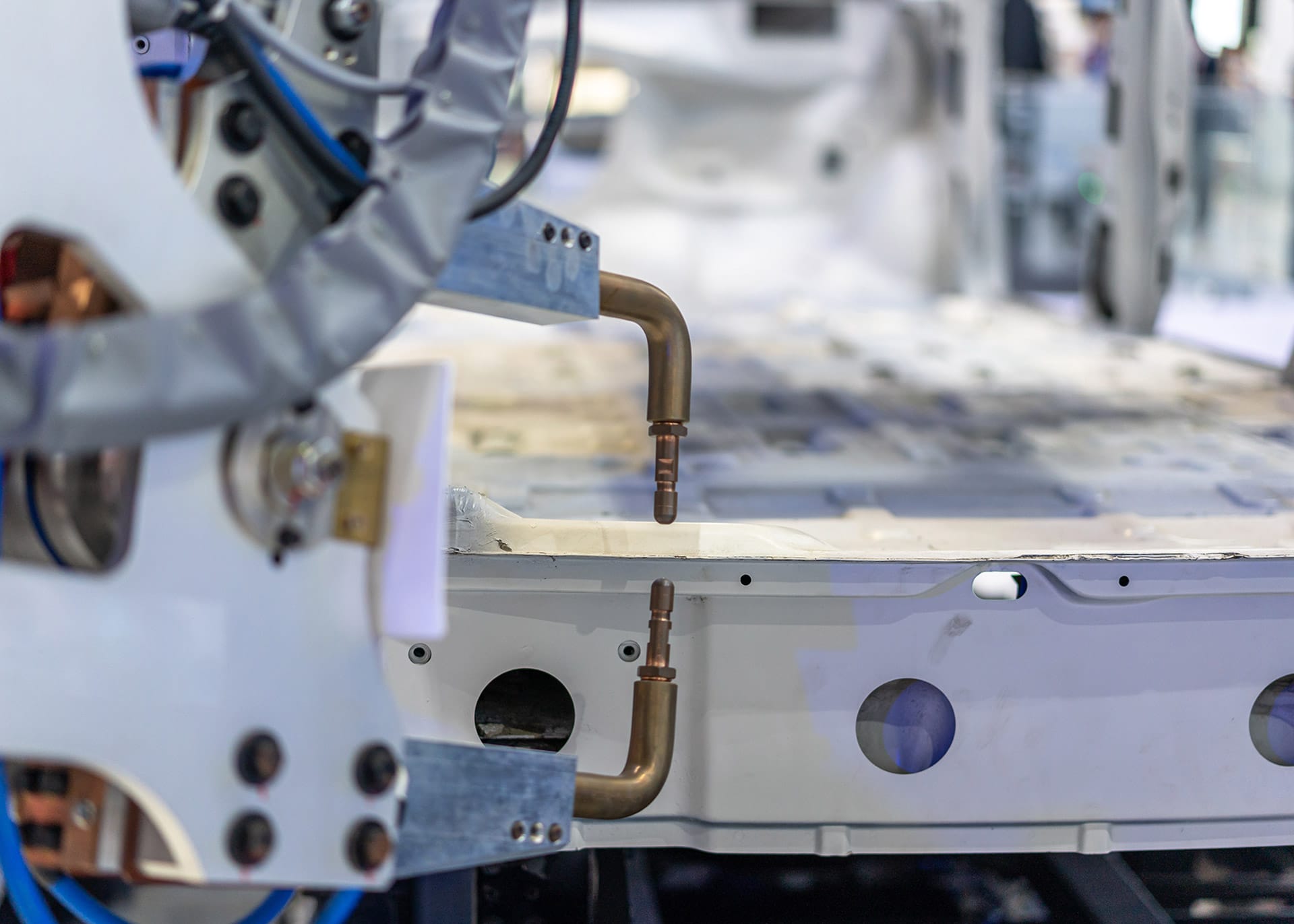

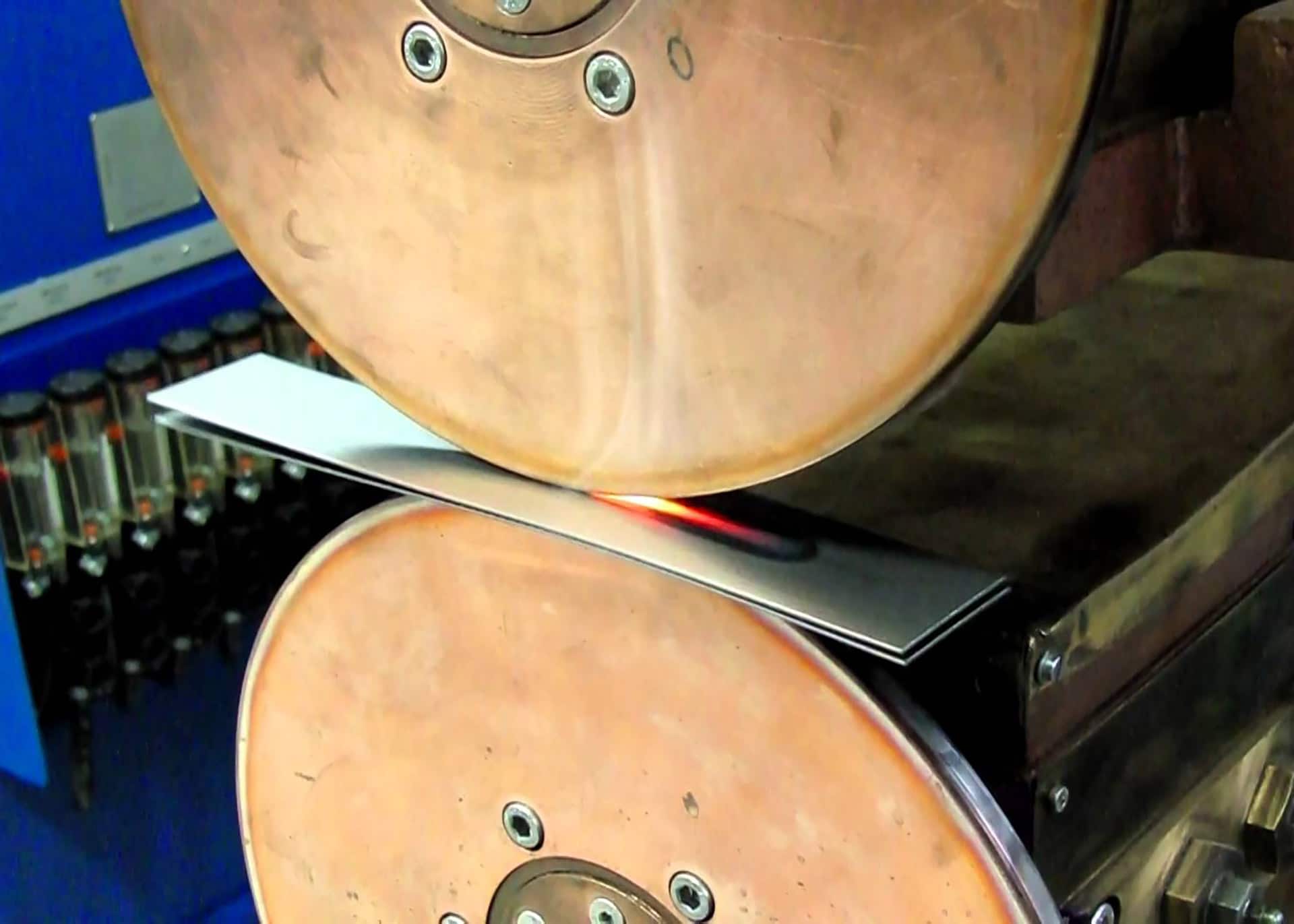

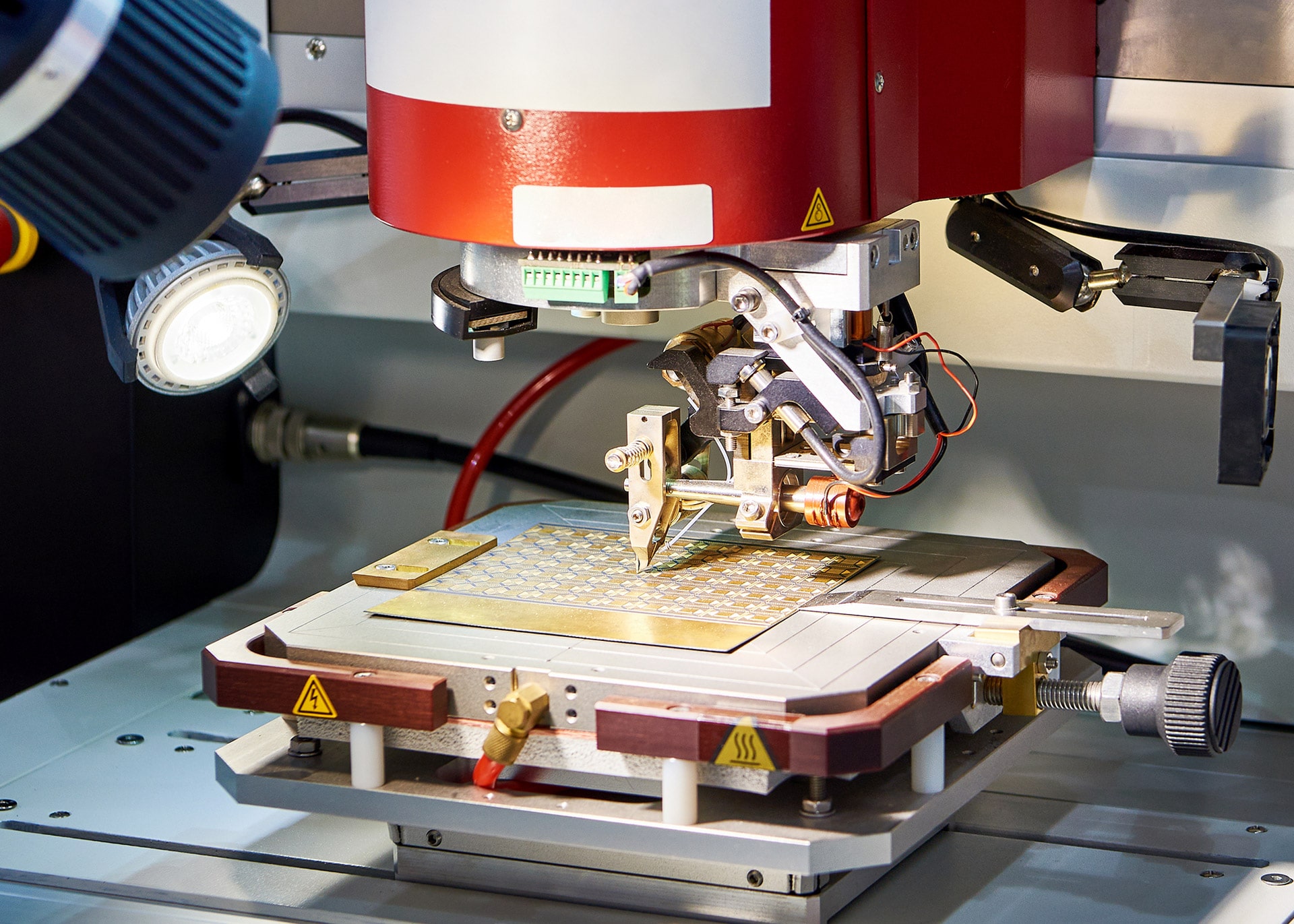

Friction welding

Friction spot welding combines the quality and process stability of friction welding with the economical and simple principle of spot welding.

Even when other processes reach their limits, friction welding is a safe and reliable solution. This “old”, reinterpreted joining technology is versatile and, thanks to its high process reliability, shows fresh perspectives in the welding industry. It is a proven joining process that has been used in production for more than three decades. In this process, components can be joined fully automatically by friction and force with a very high level of process reliability. Characteristic features here are a low welding temperature below the melting point and symmetrical heat input.

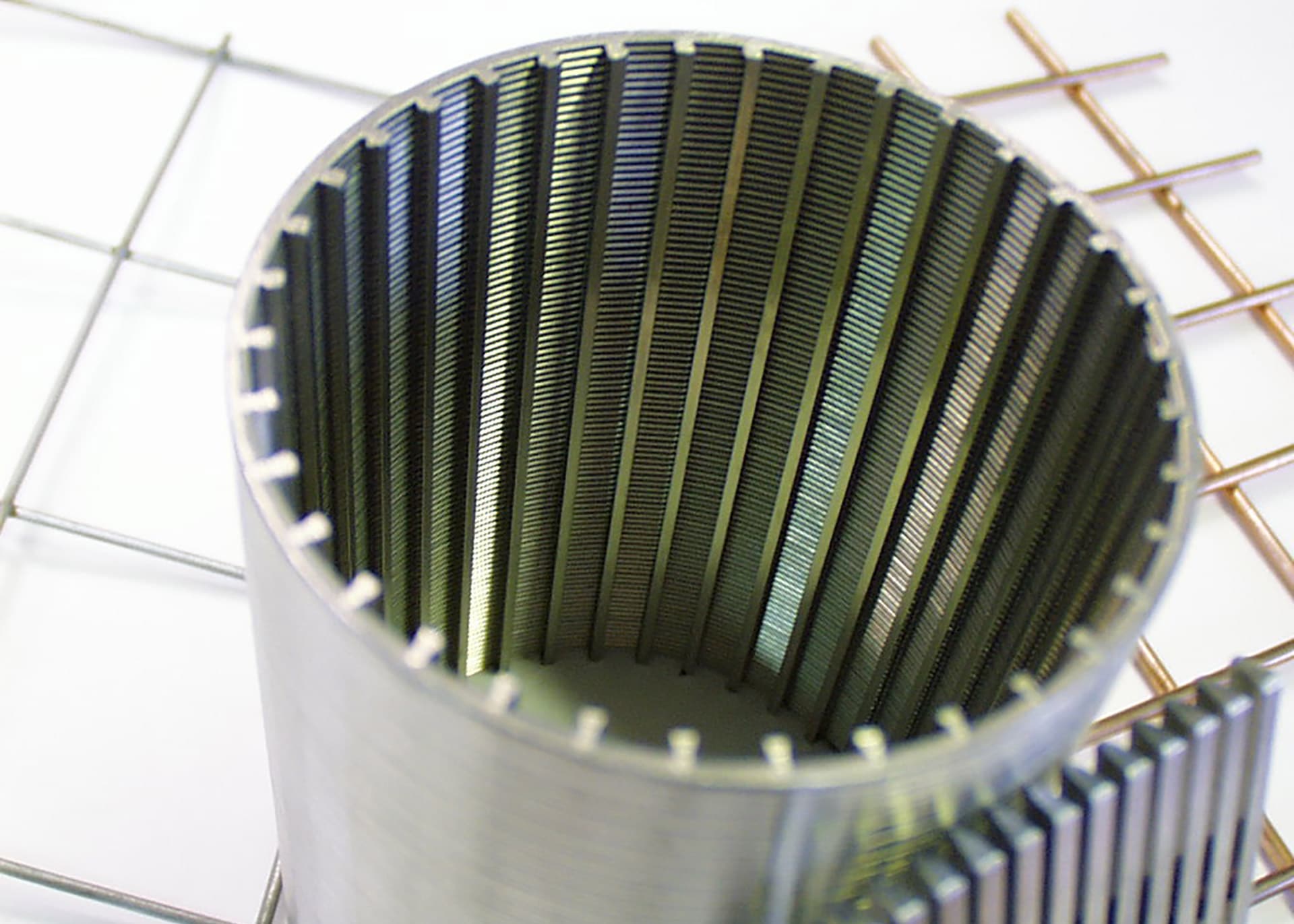

Suitable for a wide range of materials

Friction welding systems are used in the processing of a wide variety of metals. Finally, a large number of different performance classes are available to cover a wide range of weldable cross-sections and materials. The process is suitable for shaft-sheet and shaft-shaft connections, steel, aluminum, ceramics, brass and copper, among others. In addition, the process offers the advantage that it is almost independent of the conductivity and surface properties of the materials.

Downloads