Harms & Wende

Segments

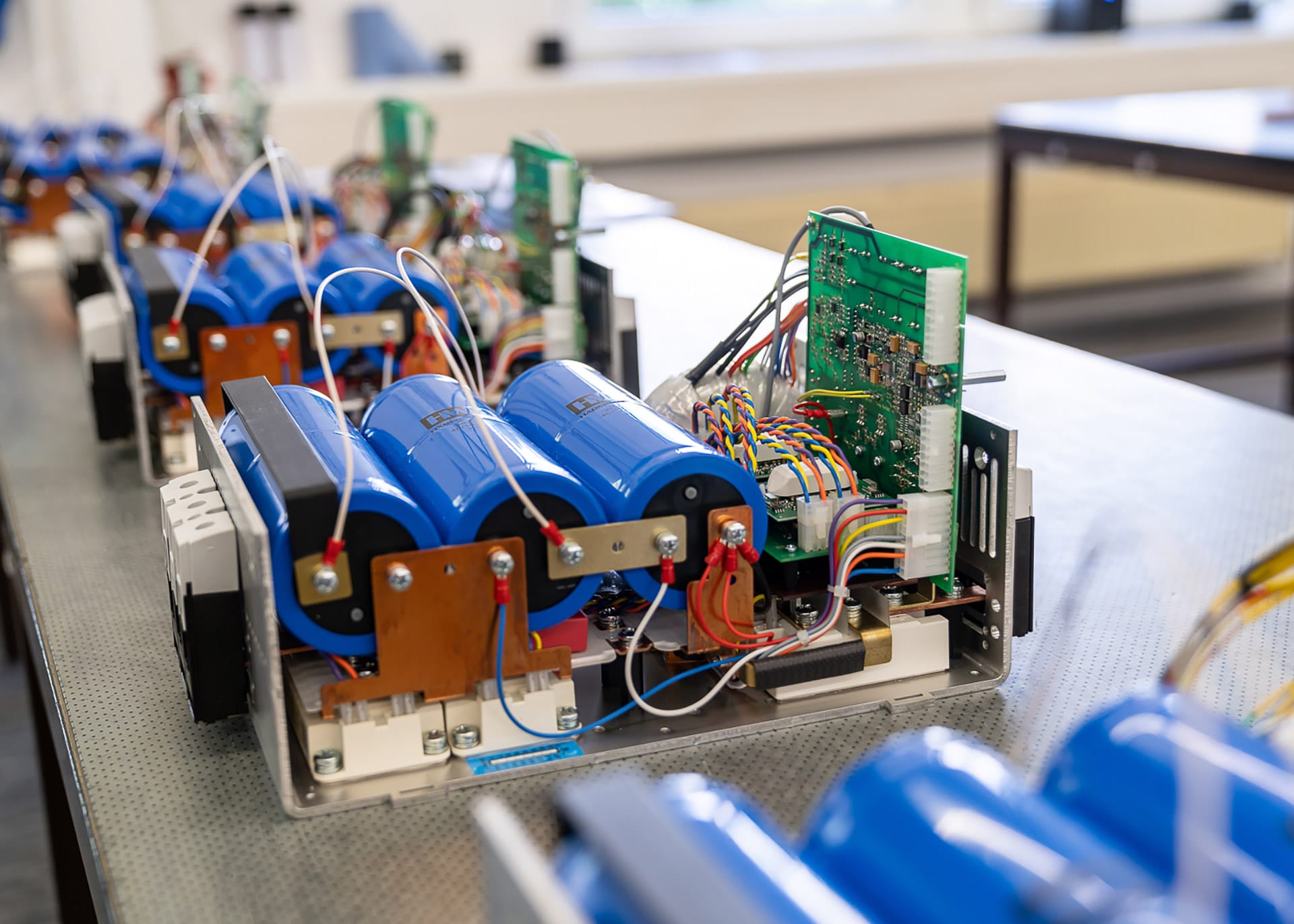

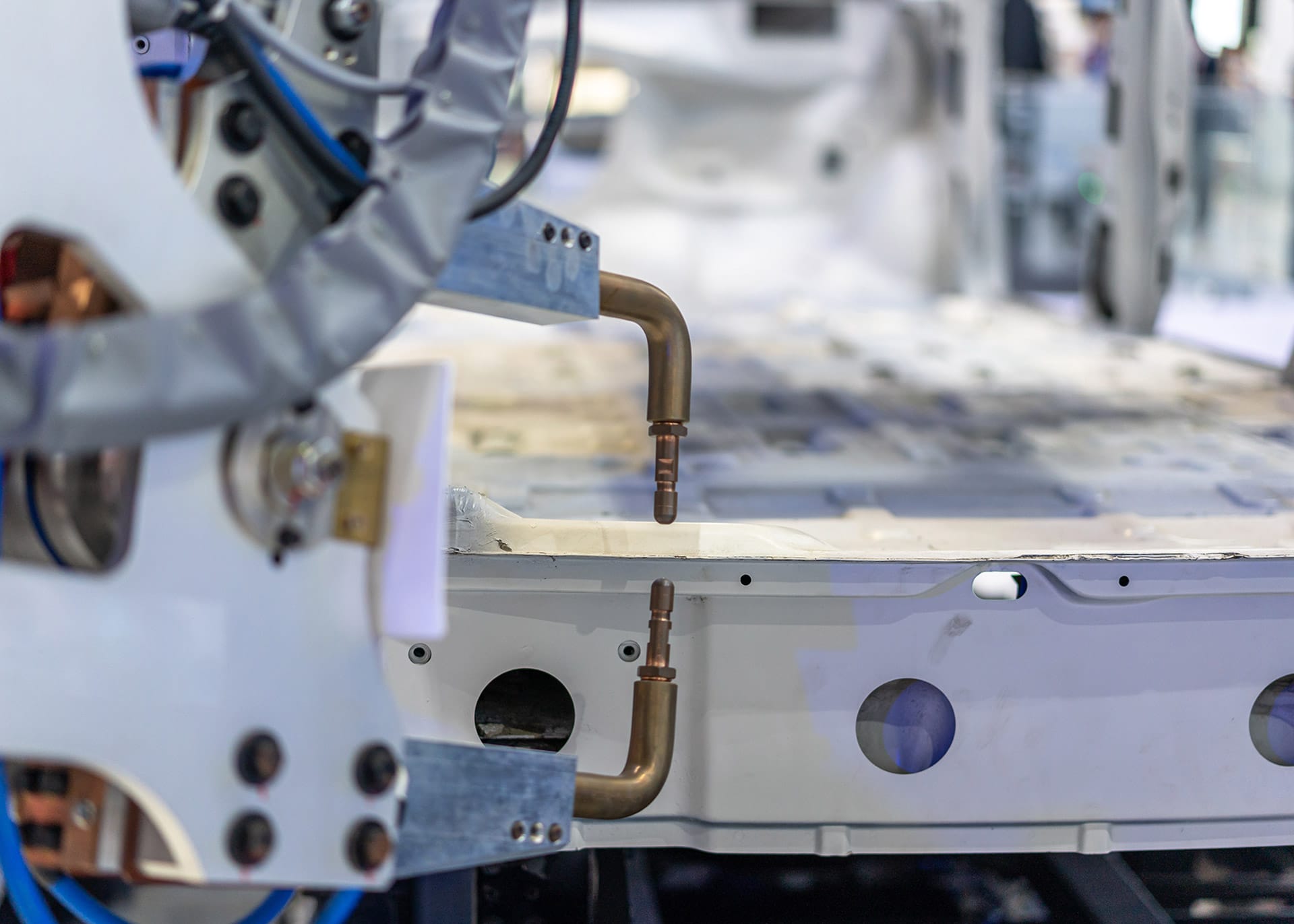

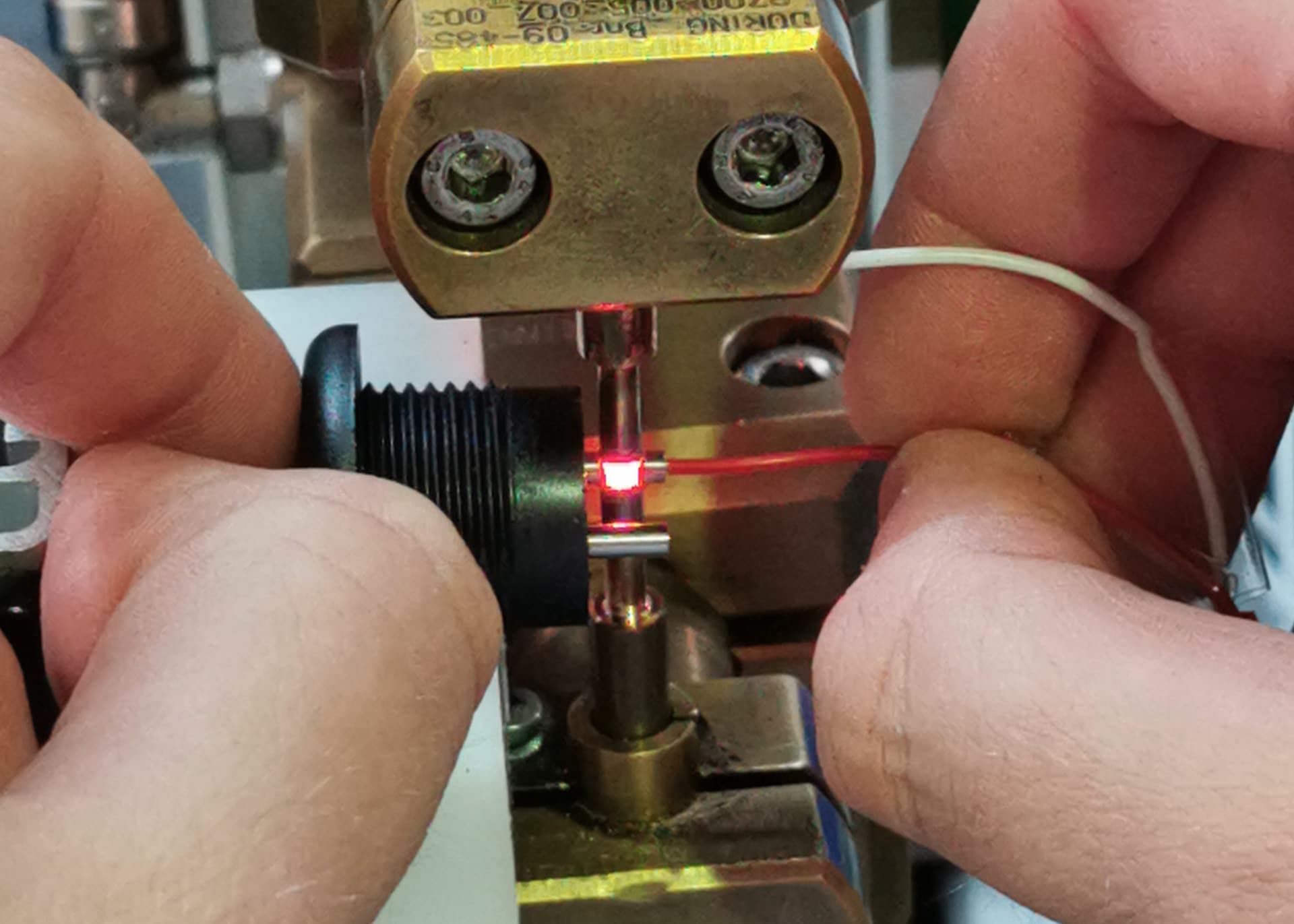

With our system portfolio, developments and experience, we cover the entire spectrum of resistance and friction welding. In doing so, we set high standards in the use of innovative technologies – be it as a pioneer of medium frequency or as a forerunner for adaptive controls and inline monitoring systems. In order to be able to meet this demand in the future as well, we dealt with the possibilities of digitalization at an early stage and developed solutions that can be used to weld more efficiently, economically and individually. In addition, we now manufacture networkable products that can be integrated into manufacturing processes, thus laying the foundation for the realization of Industry 4.0The economy is on the threshold of the fourth industrial revolution. Driven by.

When developing new products, we always pursue the goal of achieving economic and technological optimization of the welding process. In doing so, we always have resource conservation and the environment in mind. The environmental award for our GeniusMFI system and the award as an eco-profit company impressively demonstrate how energy-efficient and environmentally friendly our technologies and our production processes are.

When developing new products, we always pursue the goal of achieving economic and technological optimization of the welding process.

To ensure the greatest possible process reliability, we rely on reproducible parameters during welding. Because what is reproducible is controllable and can be controlled.