Technology Center

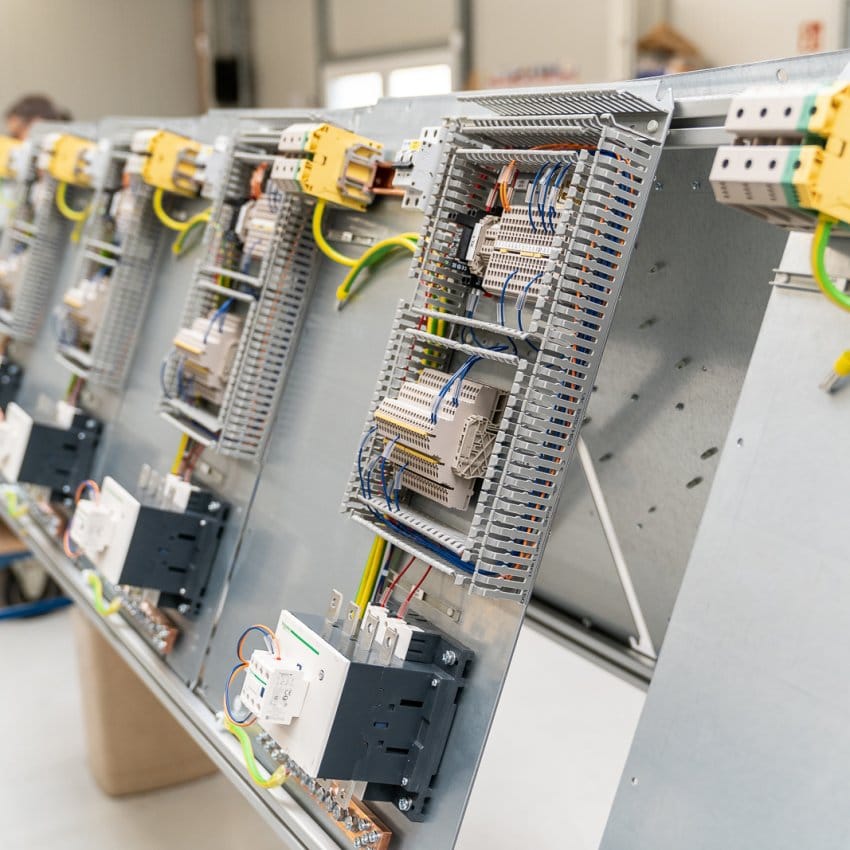

Control cabinet construction

Complete control cabinets for every need

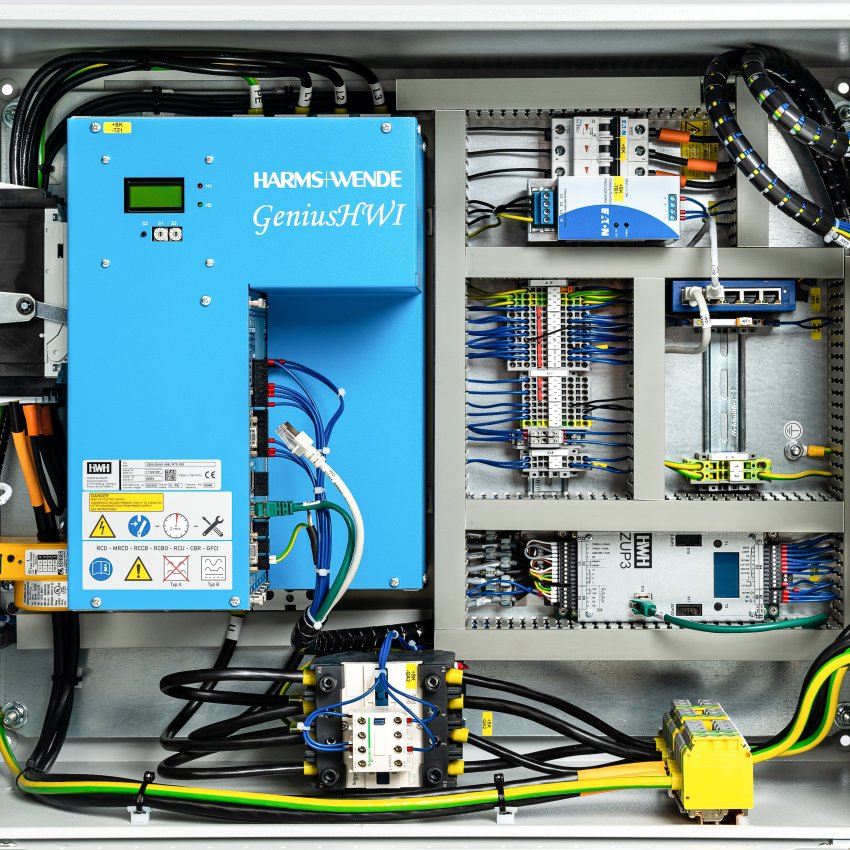

With our wide range of experience, we are able to manufacture complete control cabinets according to our own design or to customer specifications. These are equipped with high quality inverters in different power variants, as well as with main switch and power supply unit to supply the undervoltage release. Both air-cooled and water-cooled variants are available.

A control cabinet from Harms & Wende offers optimum protection of the plant technology against harmful environmental influences such as dust, water or electromagnetic interference.

In addition, the control cabinet protects the operator from touching dangerous voltages. Corresponding safety features such as a main switch and emergency stop button extend the equipment.

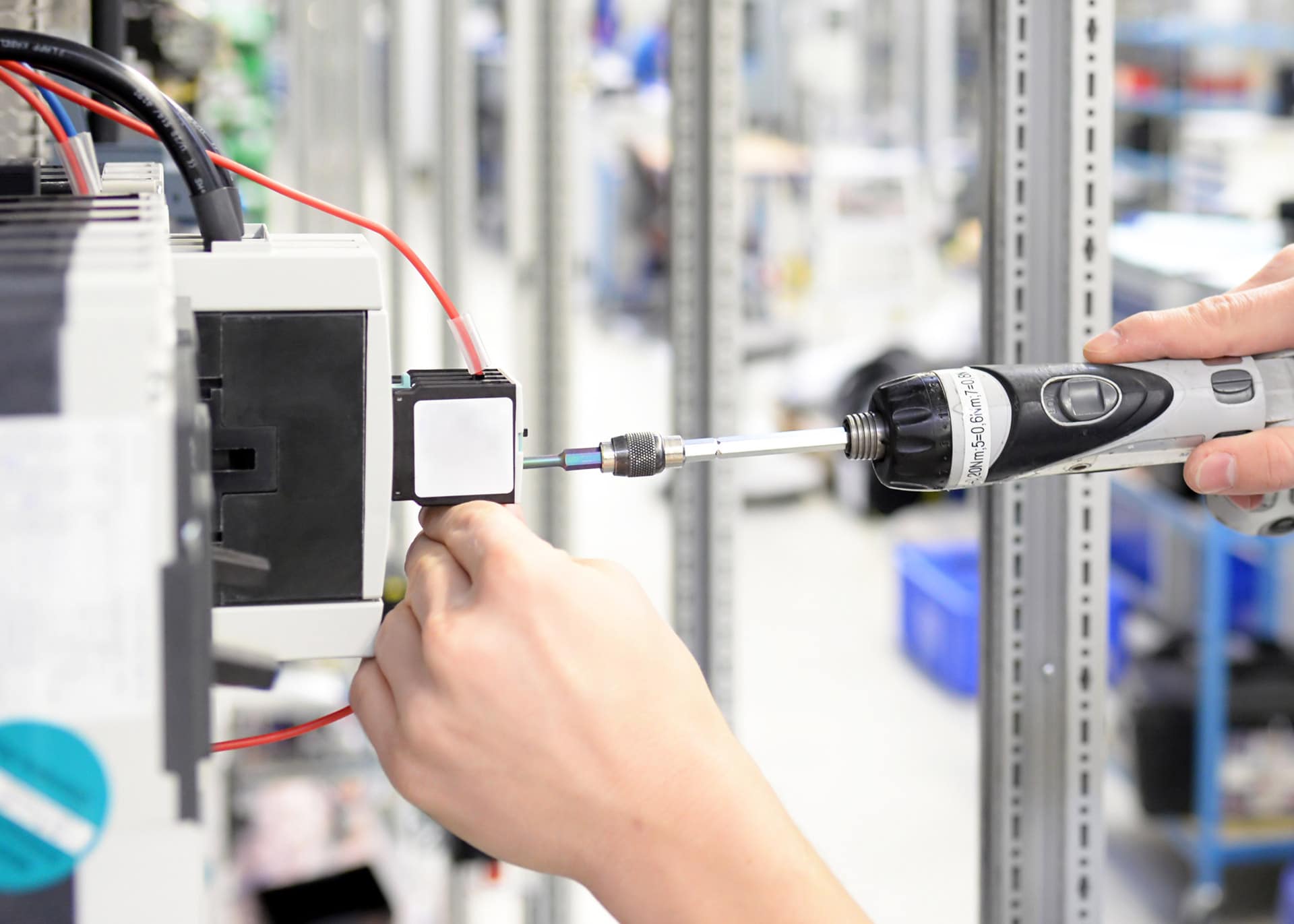

The flexible production allows the integration of control and operating elements to realize a comfortable parameterization directly at the plant.

In addition to the welding case for mounting on robot cabinets, Harms & Wende also offers customer-specific solutions as floor-standing cases. These are often used for high power inverters, for example for projection welding. Excellent accessibility to all components is guaranteed. Thanks to the generous installation space inside the control cabinet, with a simultaneously minimal footprint, additional components such as supply units or contactors can be integrated. Stand-alone housings for master-slave systems are a special feature. In these, several inverters are combined to achieve welding currents in the secondary circuit of several 100 kA.