Applications

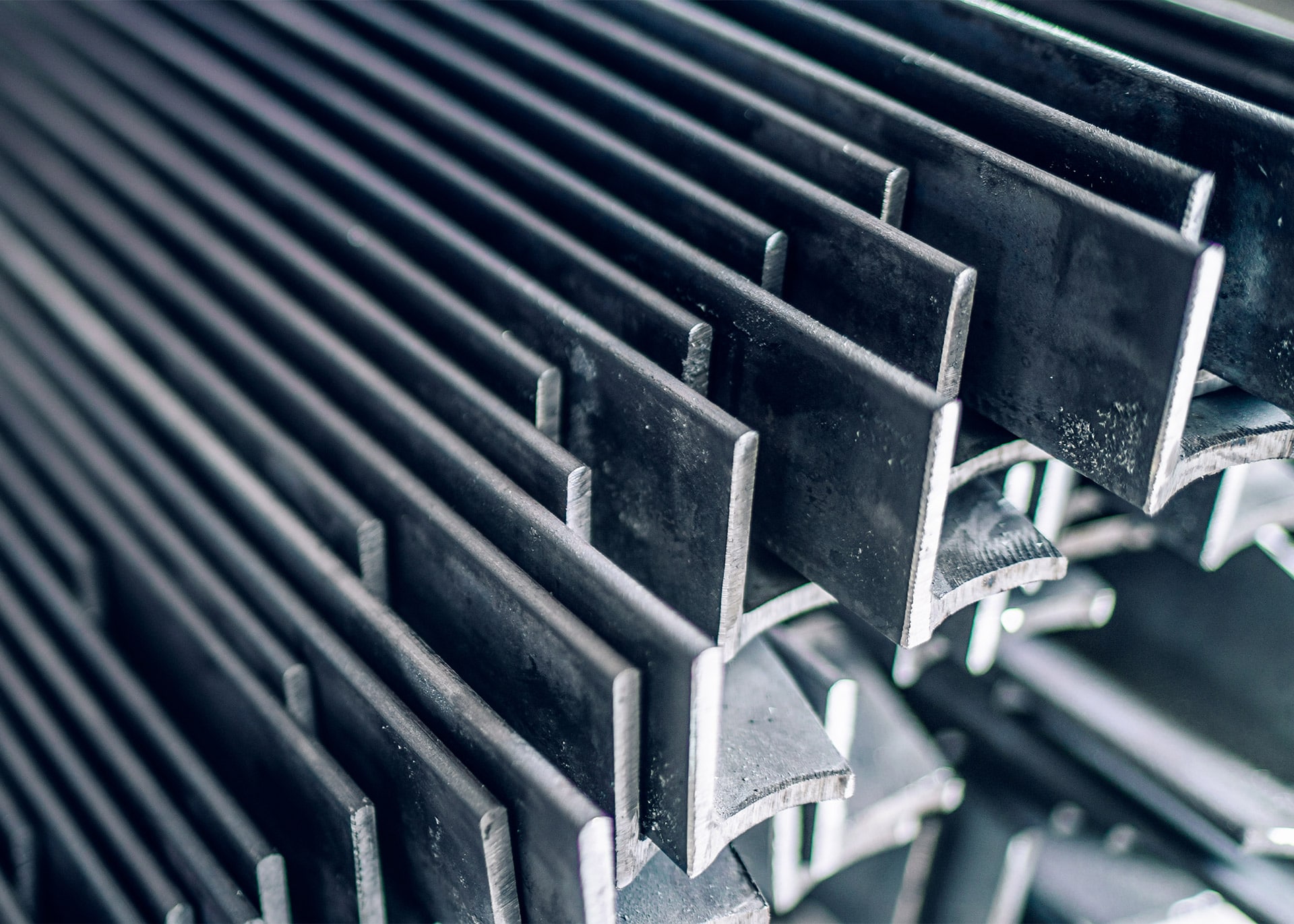

Spot welding

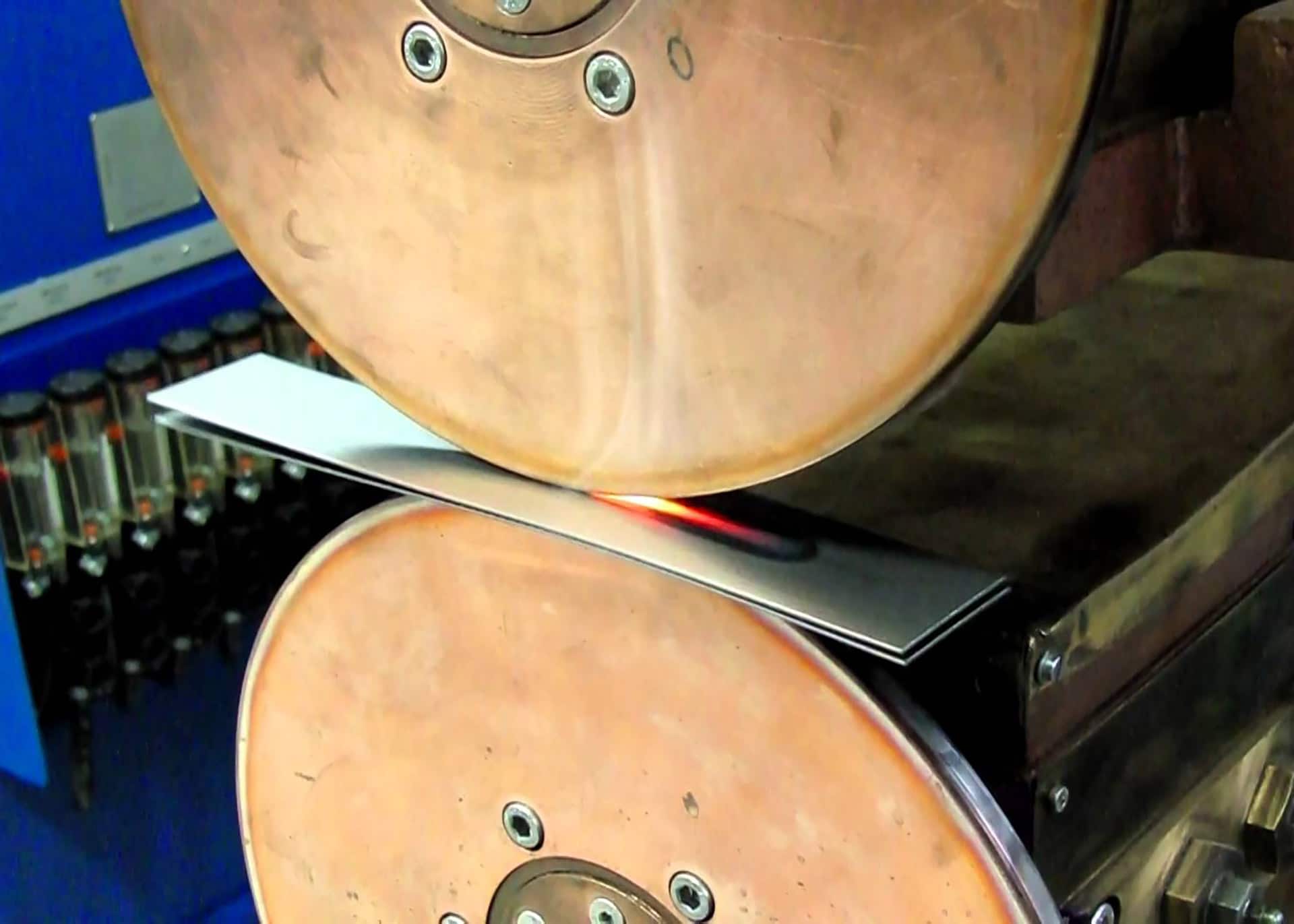

Economical, efficient and robust. This characterizes in a few words the dominant variant of resistance welding. For years, spot welding has been the undisputed No. 1 welding technique in many industries.

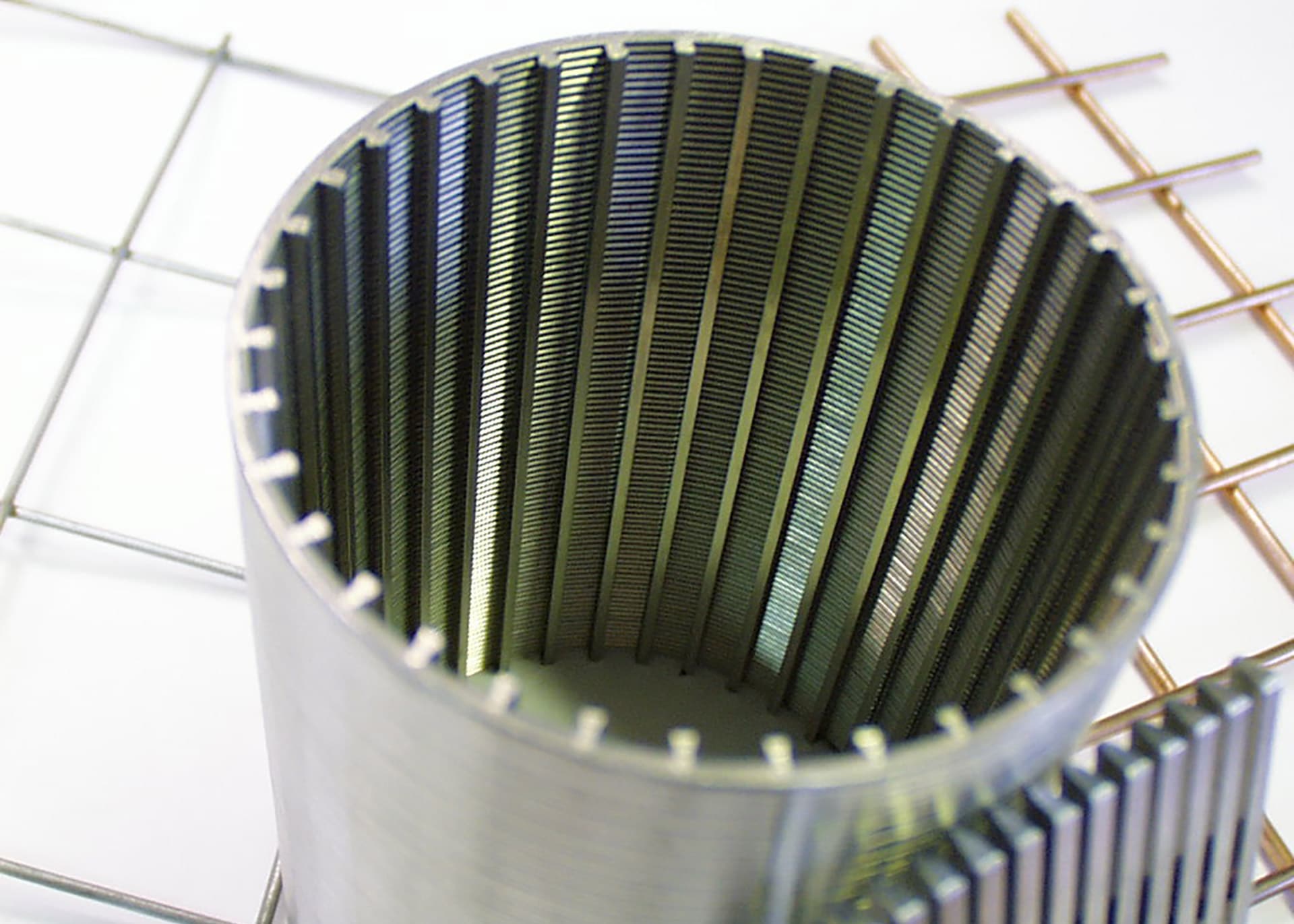

The spot welding process is always used where two sheet metal parts are to be joined without a seam. A lot of energy is concentrated onto a small area of a component using electric current. In combination with high contact pressure, this creates a virtually inseparable bond. Because the process requires no additives, such as gas or wire, takes only a fraction of a second, and is easy to handle, it is easy to automate.

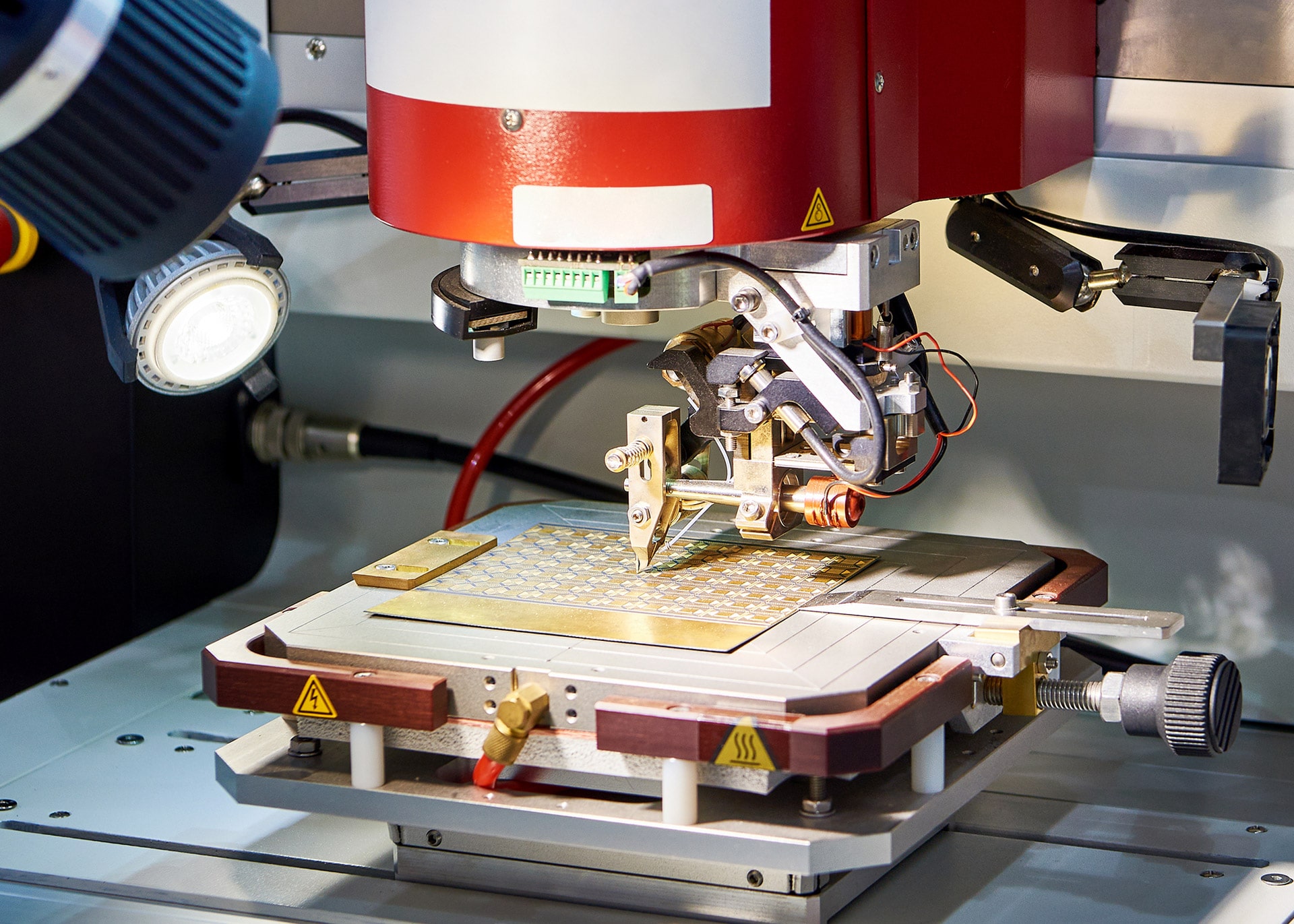

Die aktuelle Spitze der Entwicklung beim Widerstandspunktschweißen markieren heute komplett vernetzte Rohbaulinien. Adaptive controls such as IQR and true process control through powerful monitoring and inspection systems such as PQS enable safe welding of the most demanding materials.

High-strength and ultra-high-strength steel grades can be joined economically and reproducibly. By developing the IQR adaptive control system, Harms & Wende has set standards and made welding at the highest level possible. This development has made spot welding more topical than ever.