Applications

Hot staking

Hot staking or heat stacking is a resistance welding process involving enamelled wires. Since these are often only accessible on one side, a thermode is used as an electrode. The thermode, for example, consists of two tungsten electrodes that are connected to each other at the tip and thus heat up due to the flow of current, thereby transferring the heat energy to the wire. The heat melts away the wire’s enamelled insulating layer. The wire is then welded to the contact point with a second welding pulse. This is done in one operation with two welding pulses.

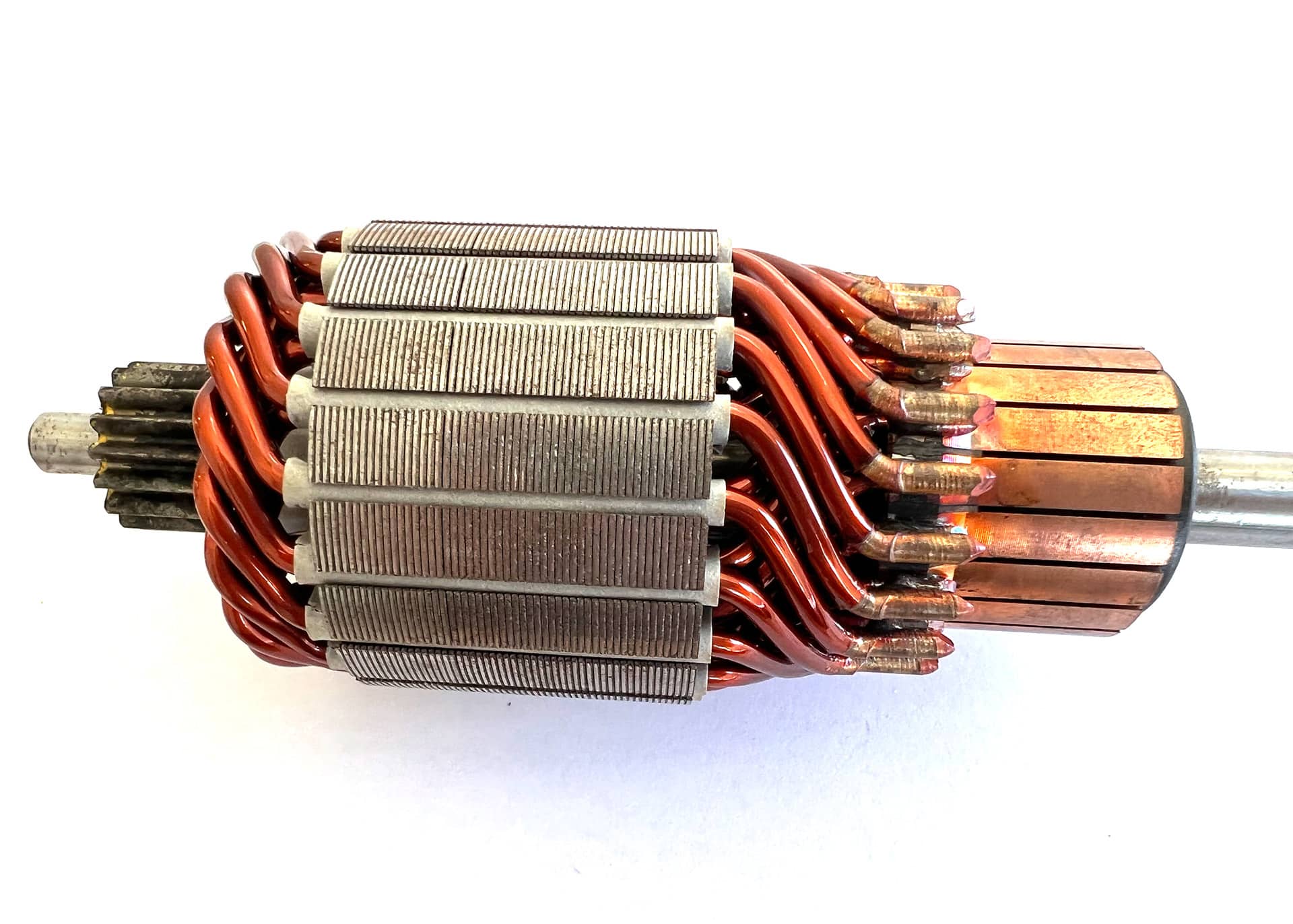

This is a diffusion weld, which does not result from melting at the contact points. This process is mainly used in the manufacture of coils, chokes, relays, motors, stators and transformers to wire strands to the contact points.