Applications

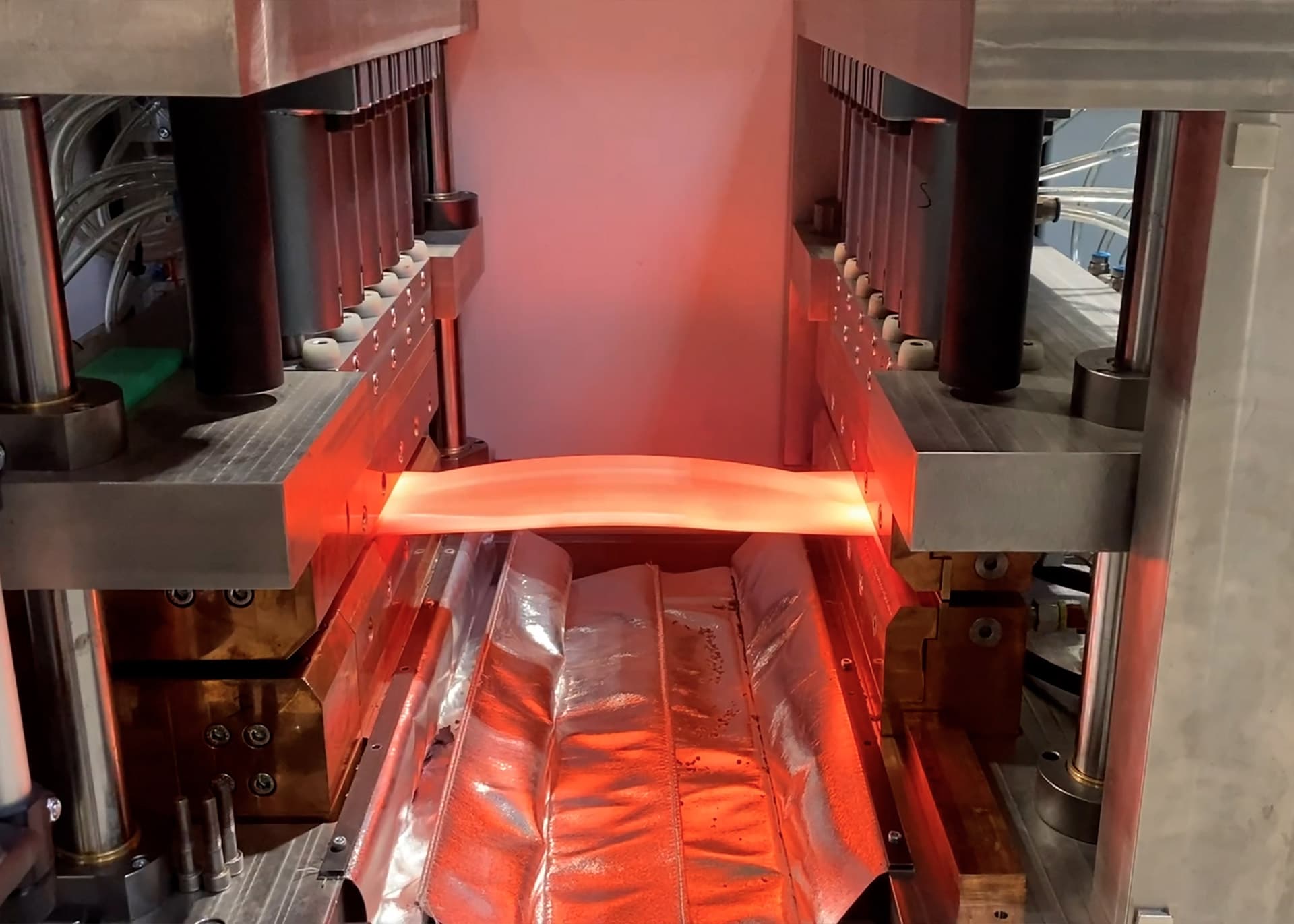

Resistance roller seam welding

Resistance roller seam welding is derived from spot welding. Spot welding machines can also be used to produce sealed seams by quickly lining up welding spots in series production. However, by moving the spot welding electrode up and down at high speed, the electrodes deform very quickly. Rotatable roller electrodes prevent these problems from occurring. As with spot welding, the roller electrodes concentrate the current on the workpiece.

This increases the service life of the electrodes while at the same time increasing the welding speed, as it is no longer necessary to open the electrodes. The rollers are driven over the workpiece so that the decisive parameters are not the current time but the welding speed together with the current level. As different welding speeds are run on one sheet, e.g. in curves, the current level must be switchable. Corresponding current profiles are used here.