Applications

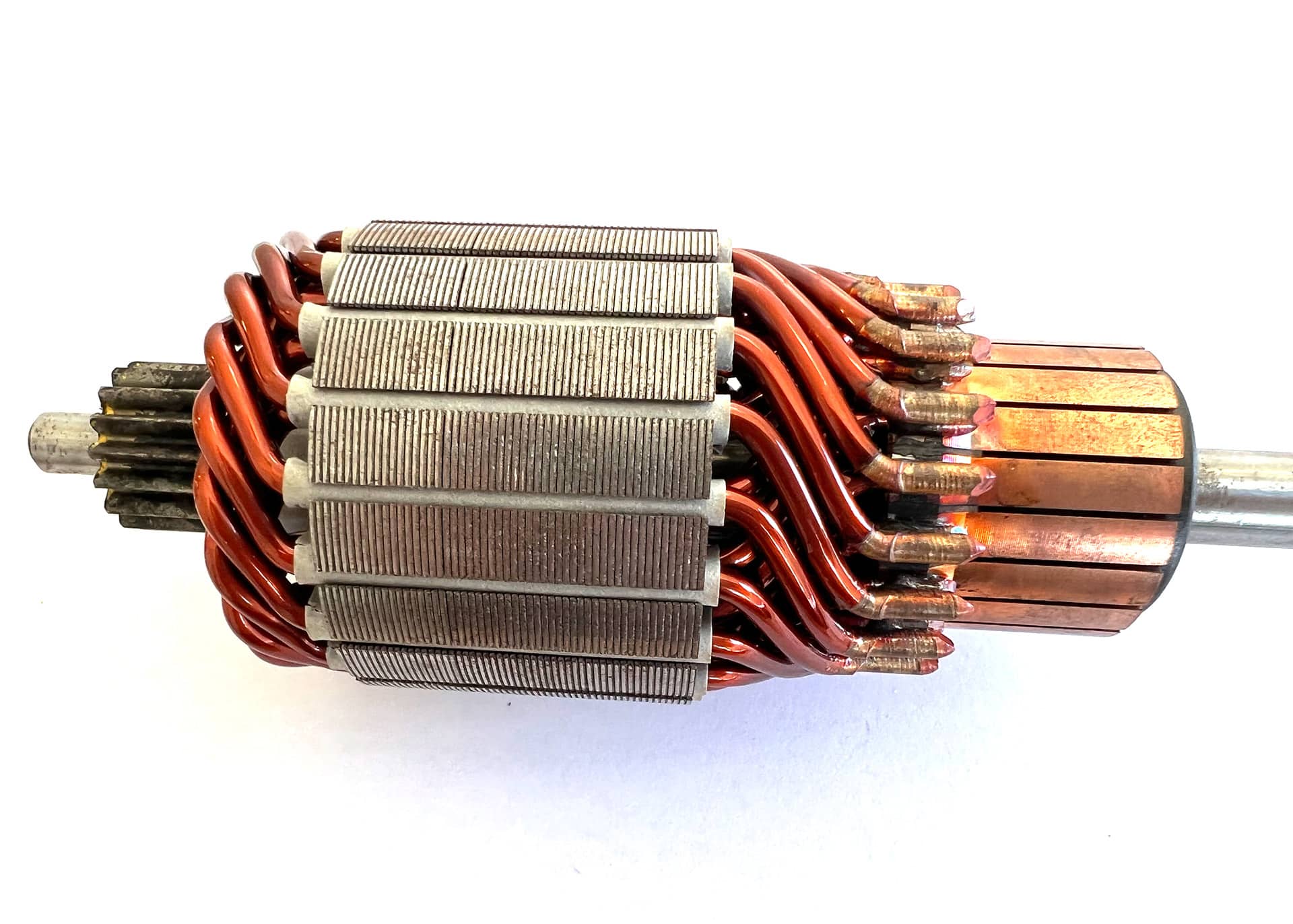

Compacting

The compacting of strands is based on the resistance heating process. A force is applied by the electrodes and a thermal energy is applied by the heat generated by the electrodes. The difference to the usual resistance welding methods is that poorly conductive materials based on tungsten and molybdenum, such as tungsten-lanthanum or titanium-zirconium-molybdenum, are used instead of copper electrodes.

These electrode materials apply the thermal energy to the strands, which absorb this heat very quickly. Here it is important to note that the heating process is completed before the copper strands are melted. The degree of compaction here determines the force used as well as the length of the welding time and the amount of welding current.