Applications

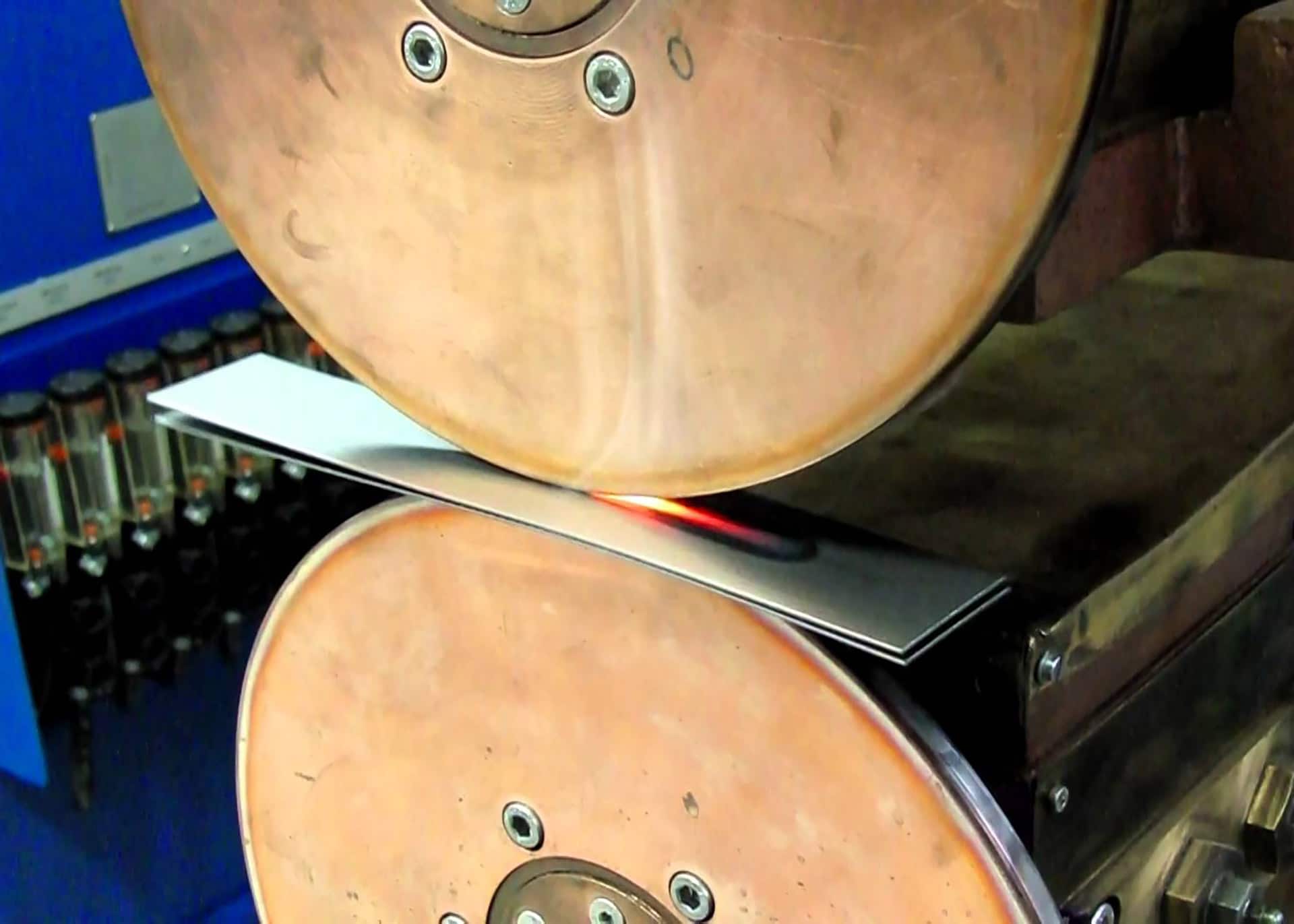

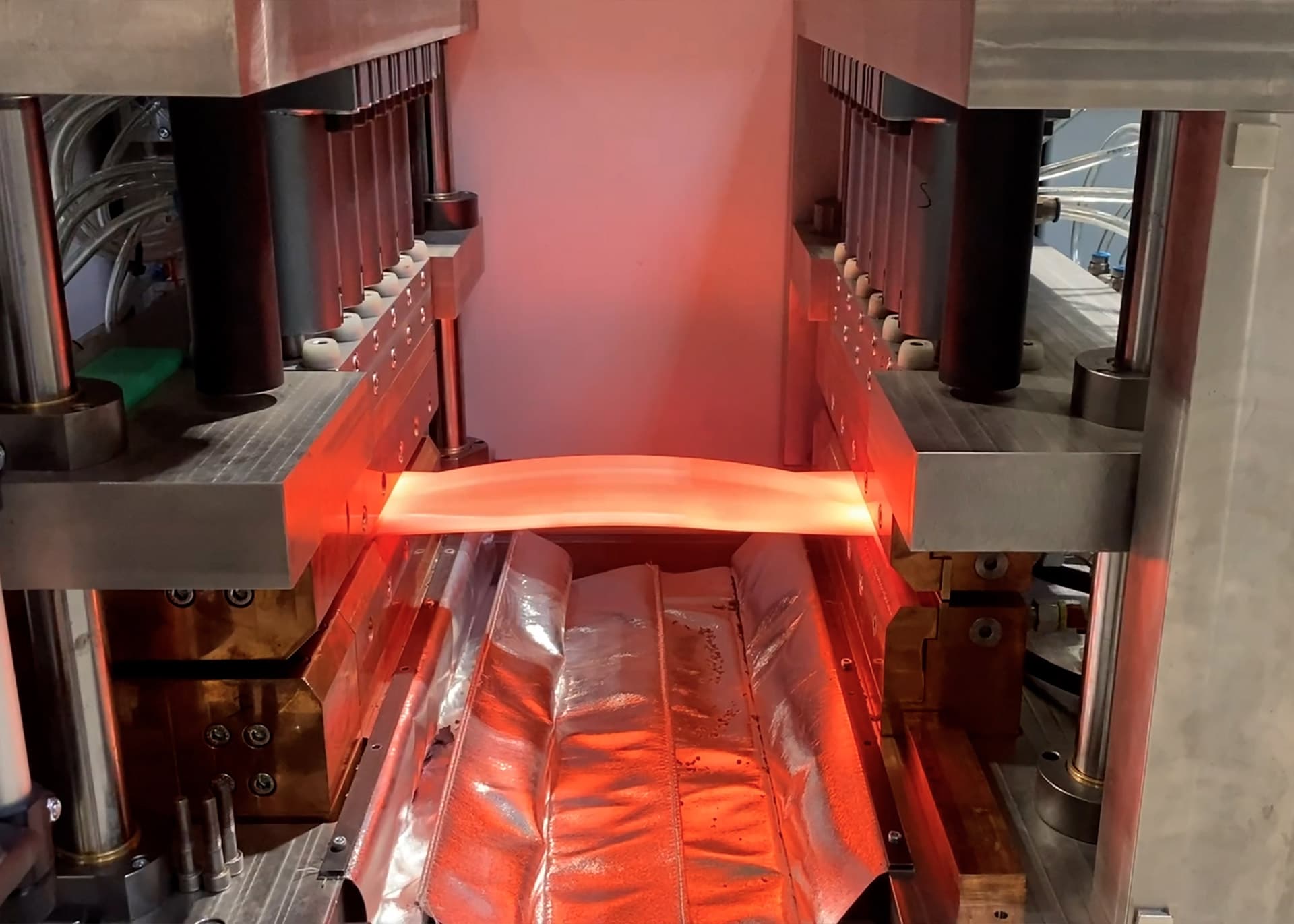

Resistance soldering

Resistance soldering differs from resistance welding in that it uses an additive called solder. It is a thermal process whereby a material bond is produced by melting a solder and diffusing at the interfaces. The temperatures used depend on the solder used. The melting temperature of the base materials is not reached as a result.

Resistance soldering is based on the resistance spot welding method where times are adapted to suit the properties of the material to be welded. The main application is the joining of copper materials.