Latest news

Friction welding

… Upgrade for your production.

The friction welding systems from Harms & Wende are used wherever demanding material combinations need to be joined efficiently, safely and reliably. (The friction welding process is very simple. A workpiece is rotated and placed on a second workpiece. The second workpiece can also be rotationally symmetrical or flat.

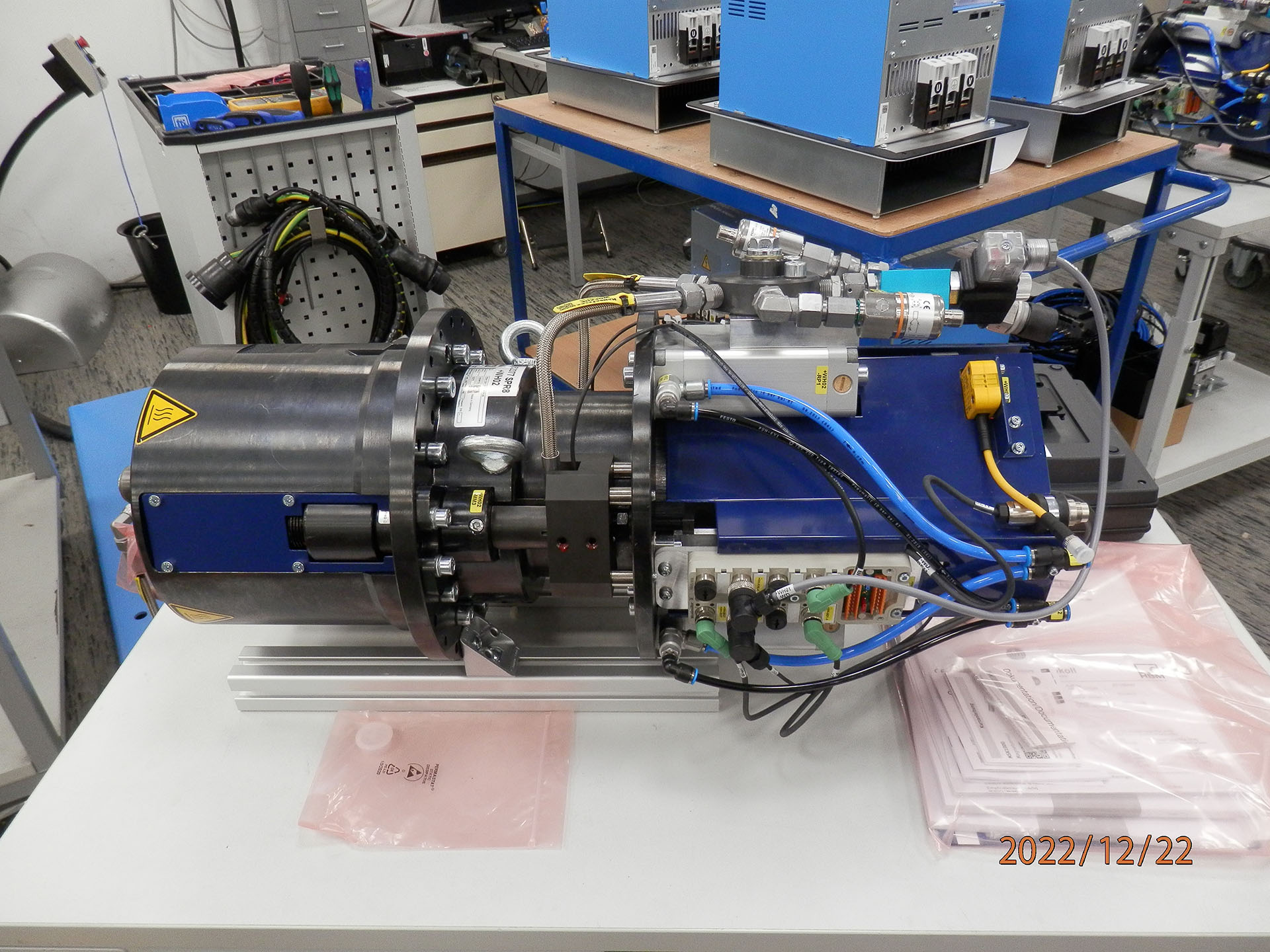

During contact, the rotation generates frictional heat which transfers the materials into a kneadable state. Once this point is reached, an upsetting movement occurs which securely joins the workpieces together). We achieve the excellent joining properties through a combination of high speed and a powerful compression unit. With our proven top system, the RSM410, we have been in continuous use with our customers for many years. The RSM410 systems complete millions of welding processes with consistently high quality. This is what makes this technology so economical. But the requirements have changed. Nowadays, of course, it is not enough just to know that the welding process is stable and reliable. The process needs to be monitored and documented.

What is already standard with our Genius medium-frequency system is now also available for the RSM410 friction welding machine from Harms & Wende. The new Rotus system has the proven and reliable hardware of the RSM410 and adds intelligent control logic based on the Genius system. This turns an RSM410 into the new Rotus system. With the XRotus user interface, process parameters can be monitored using envelope curves and each spot weld is documented in the integrated archive. This facilitates analysis and serves as proof of process stability. If you are already familiar with XPegasus, you will have no trouble finding your way around the XRotus user interface.

And we’ve saved the best for last: Almost any RSM410 can be converted into a Rotus system.

Just recently, our two service technicians Mr. Kaynak and Mr. Perez Sanchez successfully upgraded an RSM410 to Rotus for one of our customers. Thanks to their careful preparation, the upgrade was completed in a very short time and the system was ready for welding again.

Have I aroused your interest?

Write to me if you are interested in the possibilities the Rotus system offers for your production. I would also be happy to provide you with a customized upgrade offer.